Monolithic’s Condensate Ceilings: Effective, Practical, Durable

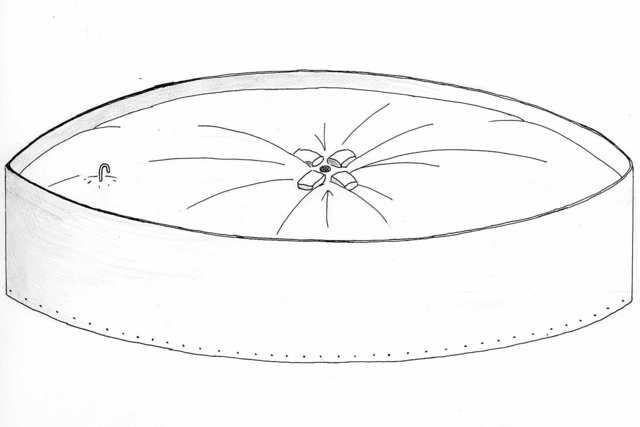

About 25 years ago: “That’s when we first started building condensate ceilings,” said David B. South, president of Monolithic. "Companies that designed huge water tanks with offices or equipment sheds built under the tanks were our customers.