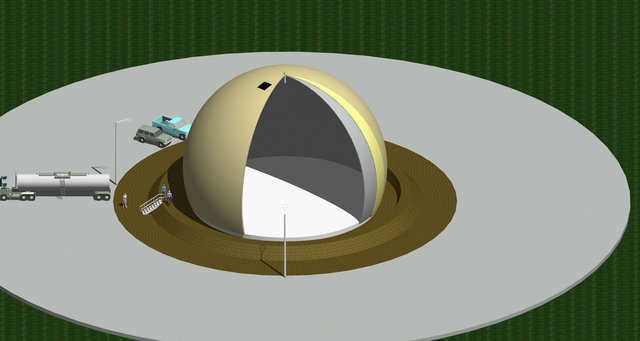

Bruco – A Very Busy Caterpillar

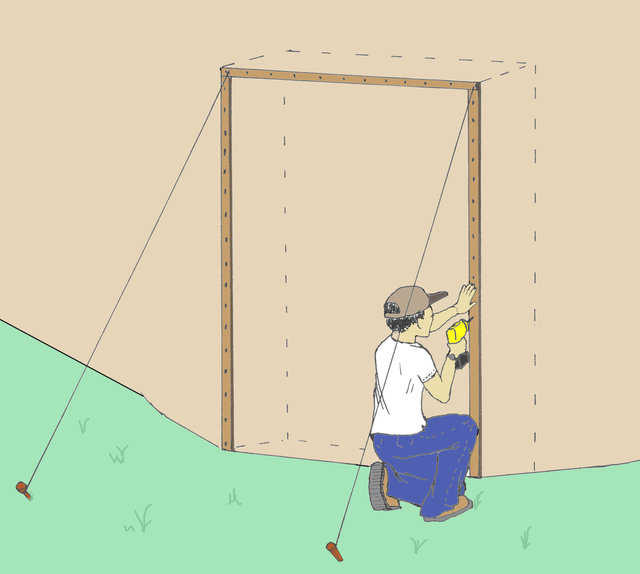

With its flirty eyes, smiley mouth and cowboy boots that glow in the dark, Bruco, our manufacturing plant in Italy, Texas, looks nothing like a typical factory. But while Bruco might look like a playful, giant caterpillar on the outside, it’s serious work on the inside.